the purification process of gold

An Overview of the Purification Process of Gold

Gold is a precious metal that has been sought after for thousands of years due to its beauty, rarity, and versatility. However, naturally occurring gold is rarely pure and is often found mixed with other minerals and metals. To produce the high-purity gold used in jewelry, electronics, and other industries, a thorough purification process is required. This article will explore the key steps and methods involved in the purification process of gold.

Why the Purification Process of Gold is Necessary

Before diving into the methods, it is essential to understand why the purification process of gold is so important. Raw gold, as it is mined from the earth, contains impurities like silver, copper, and other trace elements. These impurities affect the metal’s malleability, conductivity, and overall quality. The purification process of gold removes these unwanted substances, allowing refiners to obtain nearly pure gold, which is typically measured as 99.9% pure or higher.

Industries that rely on gold for precise applications, such as electronics and medical devices, require this high level of purity. The purification process of gold ensures that the metal is not only aesthetically appealing but also functional in various high-tech applications.

Common Methods Used in the Purification Process of Gold

There are several methods used to purify gold, each with its own advantages depending on the nature of the impurities and the desired level of purity. Below are some of the most common techniques employed in the purification process of gold.

Fire Assay and Cupellation

One of the oldest and most reliable methods in the purification process of gold is fire assay, followed by cupellation. In this method, a sample of gold ore is heated in a furnace until it melts. A substance known as “flux” is added to the molten gold, which helps to separate the gold from the impurities. The flux and impurities form a slag that floats on top of the molten gold, leaving the purified gold at the bottom. Cupellation, a specific step in this process, further refines the gold by absorbing any remaining lead and silver.

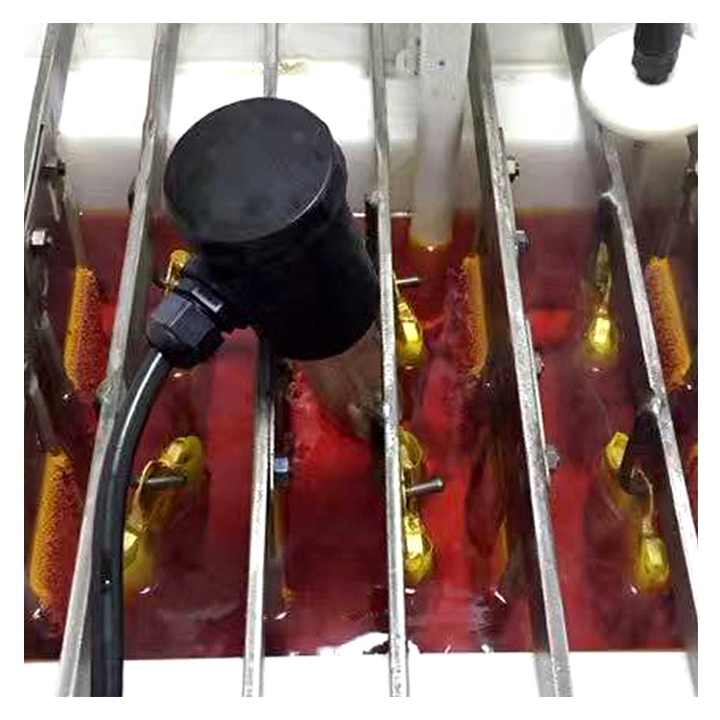

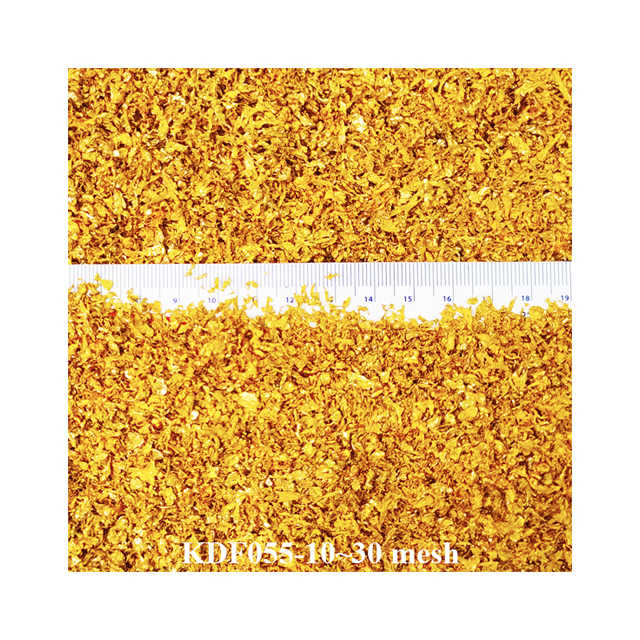

Electrolysis for Gold Purification

Electrolysis is another highly effective method in the purification process of gold, especially when dealing with scrap gold or recycled material. In this process, the impure gold is placed in a solution known as an electrolyte, and a current is passed through it. As the current flows, gold ions from the impure sample are deposited onto a cathode, while the impurities are left behind or dissolved into the solution.

This process can produce extremely high-purity gold, making it a preferred method in industrial settings where the highest levels of gold purity are required.

Aqua Regia Refining Method

The aqua regia method is one of the most powerful chemical techniques used in the purification process of gold. Aqua regia is a mixture of concentrated nitric acid and hydrochloric acid that dissolves gold. This solution is then treated to precipitate pure gold from the dissolved material. After the gold is precipitated, it is filtered, washed, and dried to remove any remaining impurities.

Though highly effective, the aqua regia process is also hazardous due to the strong acids involved. It is typically used in laboratories and specialized refining facilities.

Environmental Considerations in the Purification Process of Gold

The purification process of gold, while essential, can have significant environmental impacts if not managed properly. Traditional methods like smelting and cupellation release harmful gases and consume large amounts of energy, contributing to air pollution and global warming. Additionally, chemical processes like aqua regia can generate toxic waste if not handled correctly.

In response to these concerns, many refiners are adopting greener techniques in the purification process of gold. For instance, some methods now recycle the chemicals used in electrolysis, reducing waste and minimizing the environmental footprint of the refining process. New research is also exploring alternative ways to purify gold using less hazardous chemicals and more energy-efficient equipment.

The Future of the Purification Process of Gold

As demand for gold continues to grow, particularly in sectors like electronics, healthcare, and renewable energy, innovations in the purification process of gold are becoming more critical. Advances in technology are likely to bring about more sustainable and efficient methods, reducing the environmental impact of gold refining.

Furthermore, the increasing interest in recycling gold from electronic waste is driving developments in purification techniques. These processes, which involve recovering gold from discarded devices like phones and computers, require highly efficient methods to extract and purify the gold from a complex mix of materials.

The purification process of gold is a crucial aspect of producing high-quality, valuable gold for various industries. Whether through traditional methods like fire assay and cupellation or modern techniques such as electrolysis and chemical refining, the goal remains the same: to achieve the highest possible purity of gold. As technology advances and the need for sustainability grows, we can expect the purification process of gold to continue evolving, making it cleaner, more efficient, and more precise than ever before.