The Smelting Of Silver

The Art of Smelting Silver: A Journey Through Ancient Techniques to Modern Innovations

Understanding the Basics of Silver Smelting

Silver smelting is an ancient process that has been refined over centuries, evolving from rudimentary methods to sophisticated techniques. This process involves extracting silver from its ore using heat and chemical reactions. At FRT Machinery, we have developed state-of-the-art equipment that streamlines this process while maintaining the integrity of the metal.

Preparing Silver Ore for Smelting

Before silver can be smelted, the ore must undergo preparation to remove impurities and increase the concentration of silver. This stage includes crushing and grinding the ore into a fine powder, followed by a series of purification steps such as flotation or leaching. FRT Machinery offers advanced ore processing machines designed to enhance efficiency and reduce environmental impact during these initial stages.

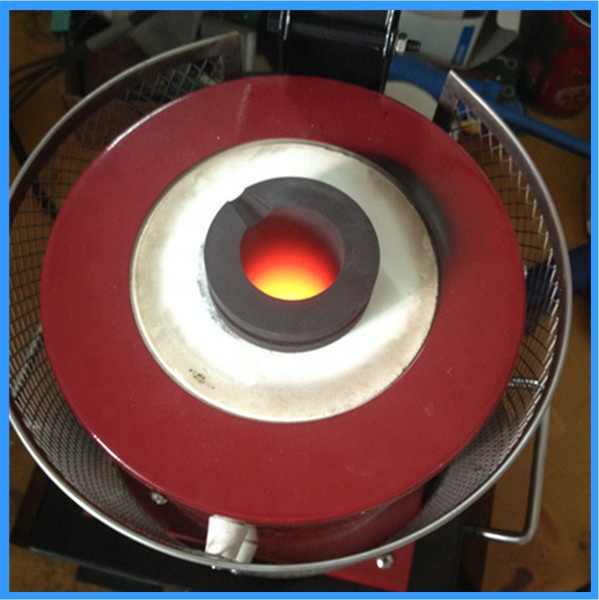

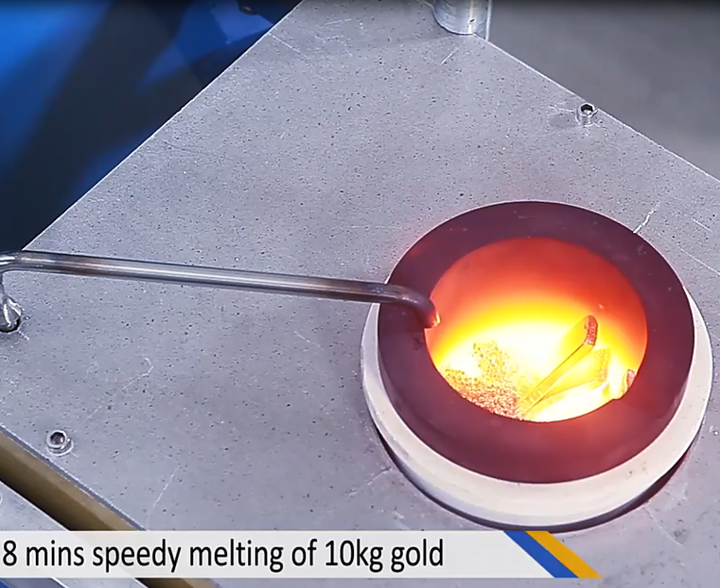

The Crucial Role of Furnaces in Silver Smelting

Furnaces are the heart of any smelting operation, including silver. They provide the intense heat necessary to melt the ore and separate the silver from other elements. FRT Machinery’s custom-designed furnaces ensure uniform heating and optimal conditions for smelting, leading to higher yields and purer silver.

Enhancing Efficiency with Modern Technologies

Innovations in technology have significantly improved the efficiency of silver smelting. Automation, for instance, allows for precise control over variables like temperature and duration, resulting in consistent quality. FRT Machinery integrates cutting-edge technologies into its equipment, making it easier for operators to manage the smelting process effectively.

Environmental Considerations in Silver Smelting

While silver smelting is essential for various industries, it also poses environmental challenges due to emissions and waste. FRT Machinery addresses these concerns by incorporating eco-friendly features into its machinery, such as emission control systems and waste recycling processes. These efforts not only help protect the environment but also comply with stringent regulations.

The Future of Silver Smelting with FRT Machinery

Looking ahead, the future of silver smelting lies in continuous improvement and innovation. FRT Machinery is committed to researching and developing new methods that will further enhance the sustainability and efficiency of silver smelting. By investing in research and development, FRT Machinery aims to set new standards in the industry, ensuring that silver smelting remains a viable and environmentally responsible practice.

Through these advancements, FRT Machinery continues to support the global demand for silver while upholding principles of sustainability and efficiency. Whether you’re a small-scale artisan or part of a large industrial operation, choosing FRT Machinery means partnering with a leader in innovative smelting solutions.