use of borax in gold smelting

Use of Borax in Gold Smelting An Essential Component for Purification

Gold smelting is a critical process used to extract gold from its ores and other materials. It involves melting the metal at high temperatures and separating it from impurities. One of the essential substances used in this process is borax. This article will explore the use of borax in gold smelting, highlighting its function, benefits, and importance in producing pure gold.

What is Borax?

Borax, also known as sodium borate, is a white, crystalline mineral that has been widely used for various industrial and household purposes. It is a naturally occurring compound with excellent cleaning, buffering, and fluxing properties, which make it indispensable in processes like gold smelting.

The Role of Borax in Gold Smelting

Borax plays a crucial role in the smelting process by acting as a flux. A flux is a chemical agent used to help remove impurities from molten metals. When gold ore is heated to high temperatures during smelting, borax is added to bind with impurities like oxides and other unwanted materials present in the ore. This binding process helps to:

- Lower the Melting Point: One of the primary functions of borax is to lower the melting point of gold ore and other accompanying minerals. By doing so, it allows the gold to melt more efficiently, reducing the overall energy required to achieve the desired temperature for smelting. This helps make the process faster and more economical.

- Separate Impurities from Gold: During the smelting process, borax combines with the impurities, creating a glass-like slag that floats to the surface of the molten material. The slag can then be skimmed off, leaving behind pure, molten gold in the crucible.

- Protect the Gold: Borax also helps to protect the gold from oxidation during smelting. As the gold is exposed to high temperatures, it could react with oxygen in the air and form oxides, which would reduce the purity of the final product. By covering the molten gold with borax, the risk of oxidation is minimized.

Advantages of Using Borax in Gold Smelting

The use of borax in gold smelting offers several advantages, which have made it a preferred flux in small-scale and artisanal gold smelting operations worldwide. Here are some of the key benefits:

1. Cost-Effective

Borax is relatively inexpensive and easy to acquire, making it a cost-effective choice for both professional and hobbyist gold smelters. Its affordability and availability ensure that the smelting process can be conducted without the need for expensive chemicals.

2. Environmentally Friendly

Compared to other chemicals used in gold extraction, such as mercury and cyanide, borax is considered environmentally friendly. When used as a flux, it does not release harmful toxins or pollutants, making it a safer option for the environment and for workers involved in gold smelting. Many small-scale miners use borax to replace mercury, reducing environmental harm.

3. Improves Gold Purity

Borax enhances the overall efficiency of the smelting process by effectively separating impurities from the gold. This results in higher purity levels, which is essential for refining the gold further or preparing it for commercial sale.

4. Reduces Energy Consumption

By lowering the melting point of the materials involved, borax reduces the amount of energy required to smelt the gold. This is particularly important for small-scale operations that may have limited access to high-powered furnaces or other energy-intensive equipment.

The Borax Method: An Alternative to Mercury

In addition to its use in smelting, borax has gained attention as an alternative to mercury in artisanal gold mining. Known as the Borax Method, this technique allows small-scale miners to extract gold from ore without using mercury, which is highly toxic and harmful to both human health and the environment.

The Borax Method involves grinding the gold ore into a fine powder and then mixing it with borax. The mixture is heated in a crucible or smelting furnace, allowing the borax to act as a flux and separate the gold from other minerals. This method is not only safer but also yields gold with higher purity levels than traditional mercury-based extraction techniques.

How to Use Borax in Gold Smelting

To use borax in gold smelting, follow these basic steps:

- Prepare the Gold Ore: Crush the gold ore into small pieces or a fine powder, ensuring that all particles are small enough to melt uniformly during smelting.

- Mix with Borax: Combine the gold ore with a suitable amount of borax, typically in a ratio of 1 part borax to 10 parts ore, depending on the ore’s composition. The borax will act as a flux to help remove impurities.

- Heat in a Crucible: Place the mixture in a crucible and heat it in a smelting furnace until the gold and borax melt. The borax will bind with the impurities, forming a slag that floats to the surface.

- Remove the Slag: Skim off the slag from the molten gold. The slag will contain most of the impurities, leaving behind purer gold.

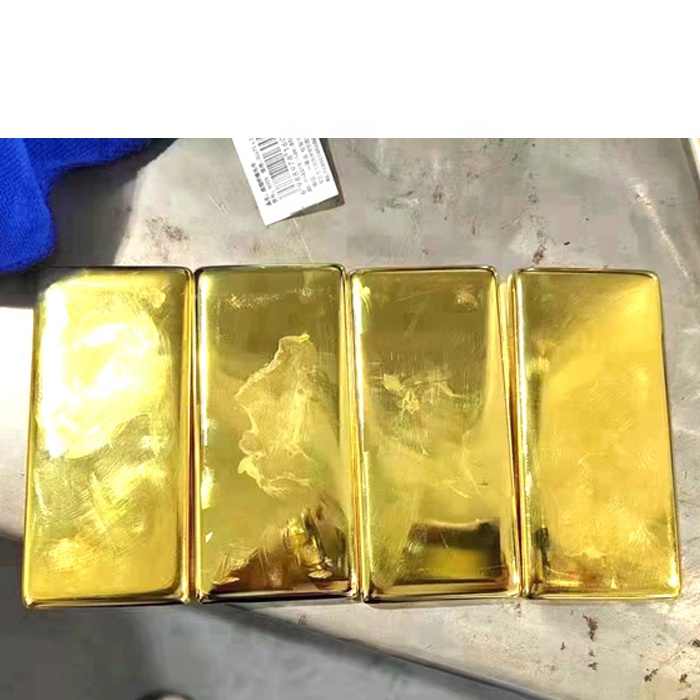

- Pour the Molten Gold: After removing the slag, pour the molten gold into a mold and allow it to cool. The result will be a gold bar or nugget with fewer impurities.

Safety Considerations

Working with high temperatures and molten metals comes with certain risks. It is important to follow safety precautions when smelting gold with borax:

- Wear Protective Gear: Always wear heat-resistant gloves, safety goggles, and protective clothing to prevent burns and injuries from hot metal and slag.

- Work in a Well-Ventilated Area: Ensure proper ventilation to avoid inhaling any fumes produced during the smelting process.

- Handle Molten Metals with Care: Use tongs and other appropriate tools to handle hot crucibles and molten gold safely.

Borax plays an essential role in the gold smelting process, offering numerous benefits, from lowering melting points and removing impurities to providing a more environmentally friendly alternative to mercury. Whether you are a hobbyist refining gold at home or an artisanal miner, understanding the use of borax in gold smelting can greatly enhance your efficiency and help produce purer gold. This ancient and cost-effective technique continues to be a valuable tool in the extraction and refinement of one of the world’s most precious metals.