what is smelting gold

What Is Smelting Gold?

Smelting gold is a fundamental process in metalworking that allows for the extraction and purification of gold from its natural ores. This technique has been used for centuries and remains essential in modern industries. But what is smelting gold, and why is it important? This article will dive into the details of gold smelting, explain its significance, and break down the steps involved in the process.

The Definition of Gold Smelting

Smelting gold is the process of applying heat to gold ore or other gold-bearing materials in order to melt the gold and separate it from impurities. This technique utilizes very high temperatures to break down the chemical bonds in the ore, allowing gold to be isolated. The purpose of smelting is to produce pure gold, free from unwanted metals, minerals, and other materials that are often mixed with the raw ore.

Why Is Gold Smelting Important?

Gold smelting is a critical step in the journey from raw ore to refined gold, which is used in various industries such as jewelry making, electronics, and financial investments. Without smelting, it would be difficult to extract usable gold from the natural materials in which it is found.

Key Benefits of Gold Smelting

- Purity: Smelting removes impurities and helps achieve high-purity gold.

- Efficiency: It enables the effective extraction of gold from ores, concentrates, or scrap materials.

- Versatility: The process works with a variety of gold-bearing materials, including ores, scrap metal, and jewelry.

How Does Gold Smelting Work?

Now that we’ve established what is smelting gold, let’s explore the process and the different steps involved. Smelting gold generally follows a few crucial steps, ensuring the removal of unwanted materials and leaving behind pure gold.

1. Preparing the Gold Ore

The first step in the smelting process is to prepare the gold ore. This can involve crushing the ore into smaller particles to improve the efficiency of the smelting process. Any materials that may interfere with smelting, such as large rocks or non-gold-bearing elements, are removed before the next steps.

2. Adding Flux

Once the gold ore is prepared, flux is added. Flux is a chemical substance, such as borax, silica, or soda ash, that helps bind with the impurities in the ore. When the mixture is heated, the flux causes the impurities to float to the top as slag, making it easier to remove unwanted materials from the molten gold.

3. Heating the Ore

The smelting process involves heating the gold ore to extreme temperatures, usually between 1,100°C and 1,200°C (2,012°F to 2,192°F). This high heat causes the gold to melt and separate from the impurities, which float to the top in the form of slag. The slag is skimmed off, leaving behind pure molten gold.

4. Removing Slag and Pouring Gold

Once the impurities have been removed as slag, the molten gold is poured into molds to cool and solidify. The solidified gold can then be further refined or used in its current form for various applications, such as jewelry or investment-grade gold bars.

Traditional vs. Modern Gold Smelting Techniques

Gold smelting has evolved from its ancient origins to incorporate more advanced technologies. While the basic principles of smelting remain the same, modern methods are more efficient and precise compared to traditional techniques.

Traditional Gold Smelting

In ancient times, gold was smelted using rudimentary tools like clay furnaces and bellows to increase the temperature. Charcoal or wood was used as fuel, and fluxes like sand or borax were added to help separate the impurities. This process required great skill and patience, as temperatures had to be carefully maintained to ensure that the gold melted without damaging the furnace.

Modern Gold Smelting

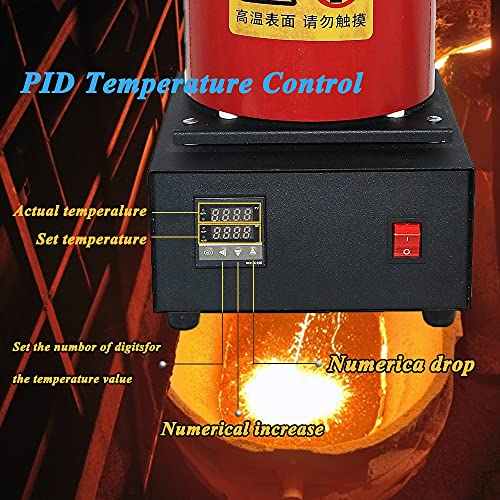

Today, gold smelting is performed using electric or gas-powered furnaces that can reach very high temperatures with precision. These furnaces allow for greater control over the smelting process, ensuring more efficient gold extraction. Modern fluxes have also been developed to improve the removal of impurities, leading to higher purity gold.

Differences Between Gold Smelting and Gold Refining

While smelting and refining are often mentioned together, they are two distinct processes. Understanding what is smelting gold is only part of the equation; gold refining comes afterward and helps achieve the highest purity levels.

- Smelting: This process involves melting the gold ore and using flux to remove impurities. The result is relatively pure gold but may still contain trace elements of other metals.

- Refining: Refining is the next step after smelting, where additional chemicals or processes are used to further purify the gold to nearly 100% purity. This is often achieved using techniques like chemical refining or electrolysis.

Applications of Smelted Gold

Smelted gold is used in various industries and applications. Below are a few ways smelted gold is utilized in the modern world:

Jewelry Making

One of the most well-known uses of gold is in the creation of jewelry. After being smelted and refined, gold is crafted into rings, necklaces, bracelets, and other ornamental pieces. High-purity gold is preferred for its aesthetic appeal and value.

Electronics

Gold’s excellent conductivity makes it valuable in the electronics industry. Smelted and refined gold is used in circuit boards, connectors, and other electronic components, especially in high-performance devices like smartphones and computers.

Investment Products

Gold bars and coins are created from smelted gold and are often purchased by investors seeking to preserve their wealth. These products are prized for their purity and are recognized as a stable store of value.

Environmental Considerations

While smelting gold is essential for producing pure gold, it is also important to consider its environmental impact. The smelting process can release harmful gases and consume significant amounts of energy, which may contribute to pollution and resource depletion. Advances in modern smelting technologies aim to reduce these impacts by improving efficiency and minimizing emissions.

In summary, what is smelting gold? It is the process of heating gold ore to high temperatures in order to separate gold from impurities. This ancient technique remains relevant today, as it provides the foundation for refining gold and producing it in pure, usable forms. Smelting is crucial to industries like jewelry making, electronics, and gold investment, ensuring the availability of high-purity gold for various applications. Understanding the importance and details of gold smelting gives us insight into the journey that gold takes from its raw form to the refined product we use today.